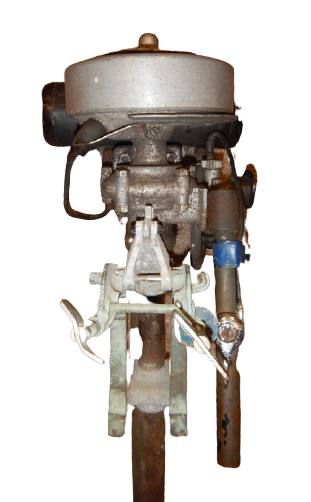

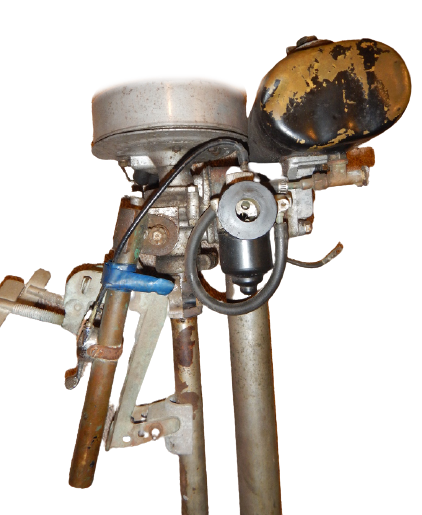

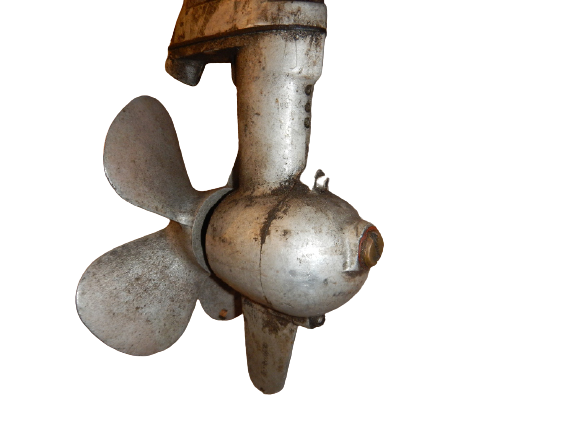

1955 Little Forty British Seagull Serial No: LS27327L

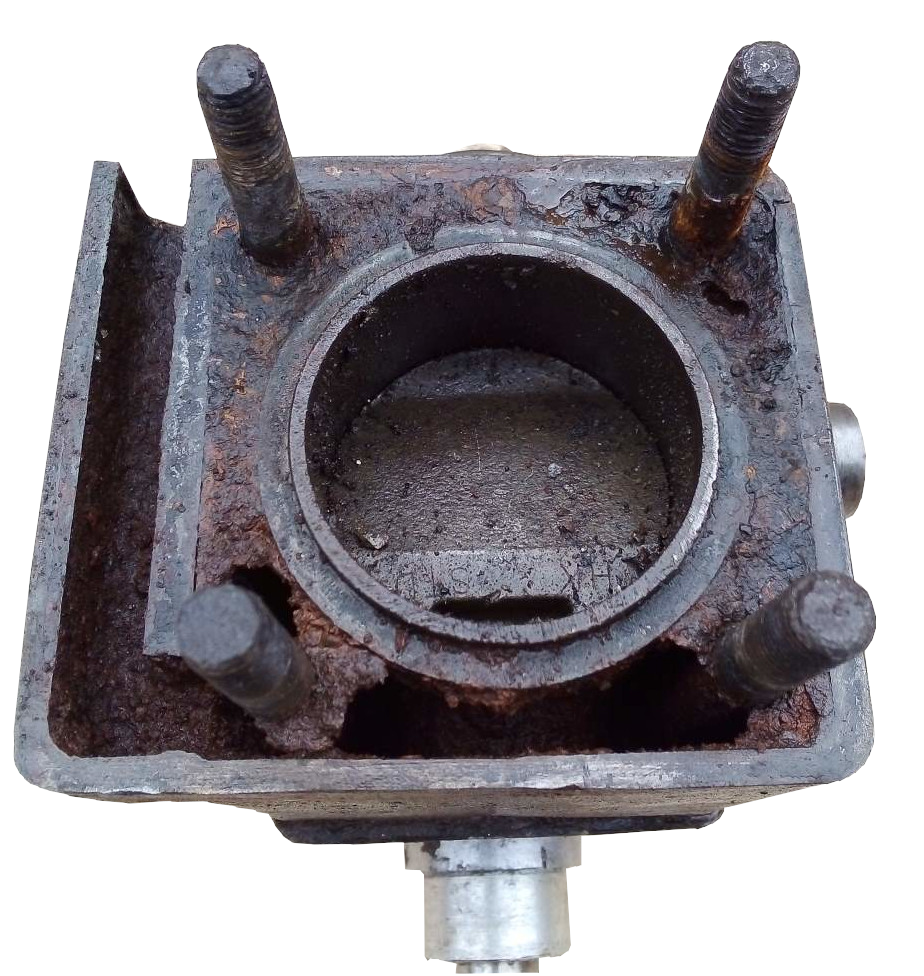

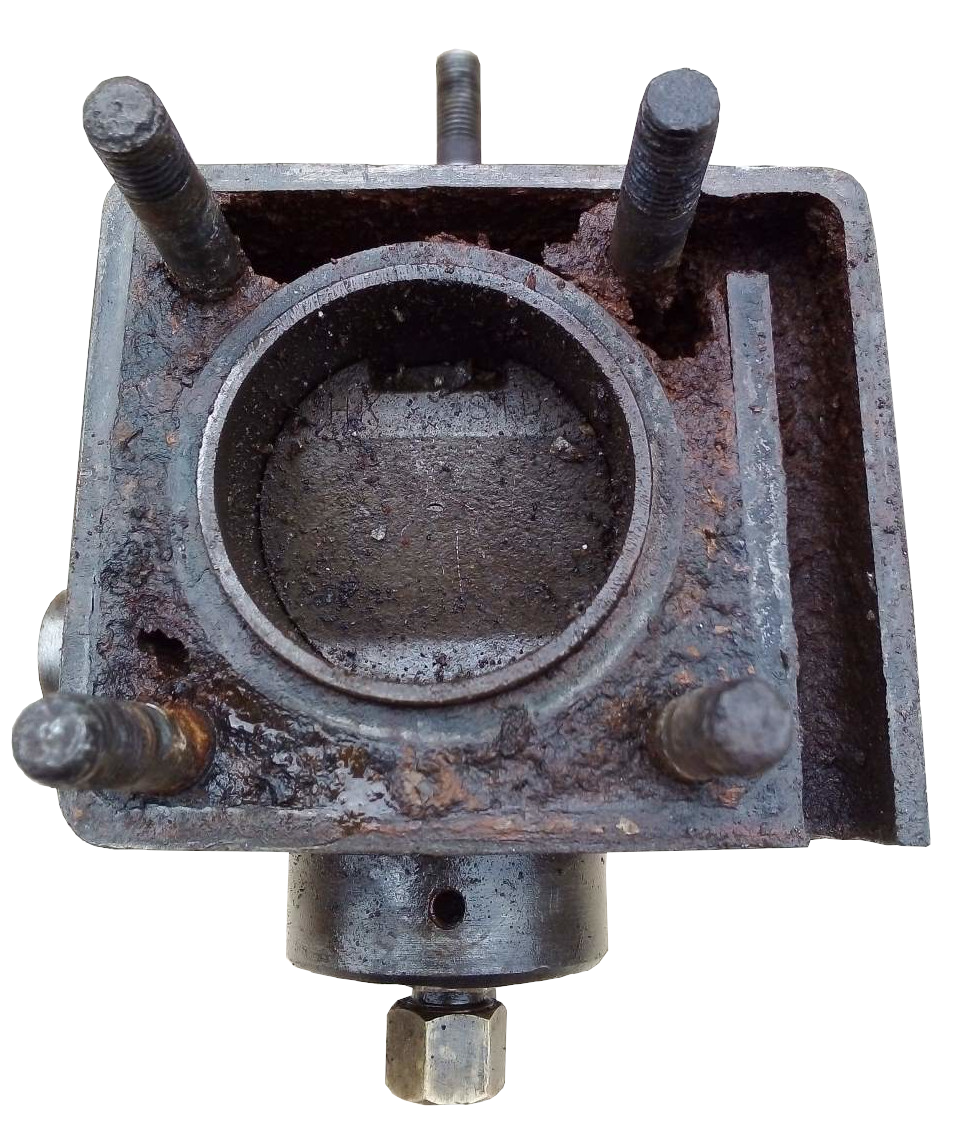

Before Photos:

These photos show it as I received it.

29 June 2021

The story so far.....

I bought this when I was away from home, working down in a regional town called Mildura, about 12 hours drive South West of Sydney. A mate was kind enough to give me open access to his shed and tools etc, so that was all the encouragement I needed to get stuck in. Turns out that same mate was born and bred in the Netherlands and spent a good portion of his youth blasting around the canals of Amsterdam in a little boat pushed along by a British Seagull, so he had a fond interest in this project.

So - disassembly......

Sounds easy. Right?

Things went well right up until the point I started.

Stripping it down was not ludicrously difficult - given its age and condition, but some of the things I found were pretty ugly.

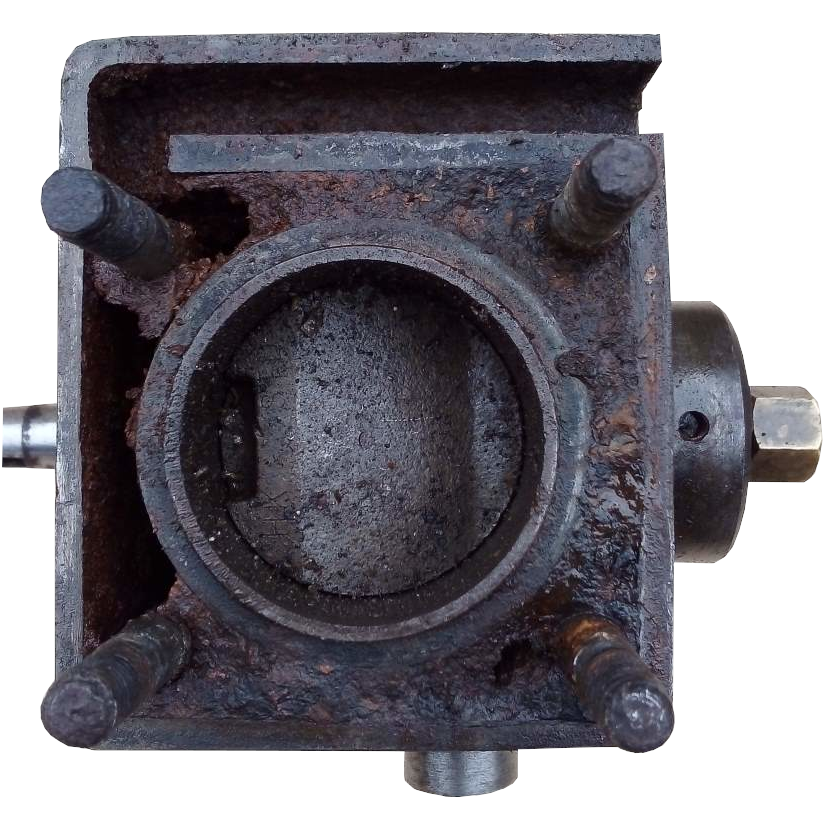

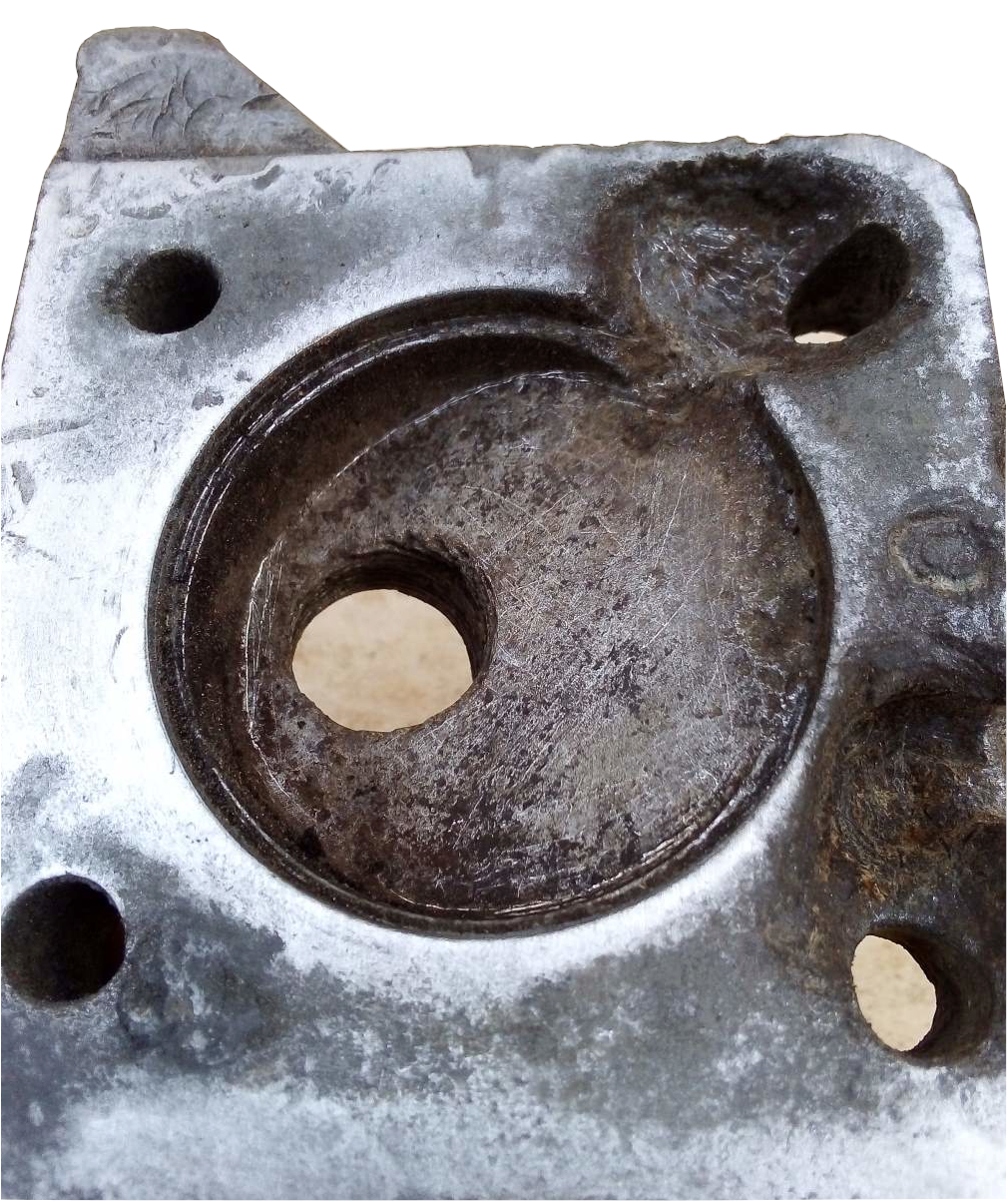

Despite my claims about it being not too difficult to get apart, one part gave me a huge amount of trouble - getting the head off the barrel. I won't bore you with the details of getting it off, but when I did get it off, this is what I found.

And there was more....the head itself was destroyed!!

All those big divets/holes weren't going to do much to help the compression.

Realistically, there is only one solution, a new head, and they are not that expensive, so that is what I will do.

But I am also going to have a go at repairing this head, and see if I can get a Seagull to run with it. My plan is to use JB Weld, an expoxy glue that I am a bit of a fan of, so see if I can use it to make the repairs. JB Weld, once cured, is very hard, supposedly like metal, and once cured it can be drillerd, tapped, filed etc. So I will fill all those big divets, file and then sand it dead smooth (sand paper on a big sheet of glass) and see how it goes. Just an experiement really, I will definitely put a new head on, I don't want the dodgy head giving away when I'm 10 miles of the Berowra Waters

8 September 2021

Well life has been a bit weird here in Australia of late - the fools running the show have locked us all away (well we do have a convict past I guess) - trouble is, I got locked away when I was away from home, and it wasn't all that easy to come home, but don't get me started. Suffice to say, I am back home now, and work can recommence on the little Seagull.

So not a lot of work done today - just enough to remind myself where I had got up to before the great freeze in Life as We Know it.

Today I got everything out of the storage tub - I found a few unexpected bits and pieces, and two drive shafts, which was a surprise. Then I remembered I had (perhaps foolishly) stored bit for two separate Seagulls in this storage tub. ONe was the little forty I am working on - LS27327 - and the other was a few bits and pieces from a 102 I as working on. I now vaguely remember thinking I didn't want to lose the 102 bits, so I thought the safest place for them was in this tub. Anyway - it is what it is....

So unload the tub, and this is what I was presented with.

11 September 2021

Back to the old Seagull. I was planning to make some good progress on this little fella, as I had 2 weeks off work, but of course tthat didn't last long - turns out my 2 weeks got interupted with mnore work, so.....

Today I gave the crankcases a bit of a clean and polish, inside and out. Made sure the brass bushes were still in good condition (they were), and gave the crankcase faces a good sanding with 400 Wet and Dry on a large sheet of glass, to get them nice and flat.

Once they were ready to go, I got the piston out, gave it a bit of a clean and reattached it to the recently repaired crankshaft. The the whole assembly, crankcase innards, piston, connecting rod, crankshaft was given a good clean, ready to go back together. Penrite Assembly Oil on the Crank, on the shells and good to go. Then Permatex Anerobic Sealer on the Crankcase faces, inssert the crankshaf/piston assembly and bolt them lightly together.

Once the sealer had had 15 minutes to semi-dry, then it was time to torque the bolts down, at 9ft/lbs.

Tomorrow I will get the barrel and head back on....maybe. I need to decide if I am going to reuse the head gasket and the Head and Base Plates. I think the Head gasket will be fine, just give it a clean up and aneal it and she'll be good to go, but the Head and Base Plates......nah....they are pretty rough. OK, that was easy, decision made - so they won't be going back together tomorrow, and tomorrow is my last day before I have to head off for 3 weeks work. Bummer.

22 December 2021

OK, this is proving just a little bit more difficult than I thought - John at Saving Old Seagulls has new Head and Base Plates advertised on his site, but just my luck, they are sold out at the moment. Luckily though, he has put me in touch with someone who may have some (John from SOS is incrediibly helpful!!), so I am currently contacting him to see if I can get any from him, failing that, I will try and get a few manufactured myself. I doubt it will be incredibly difficult or expensive. All I will need to do is measure them, find out the correct thickness and metal, and then send them of to a plasma cutter or similar. I might get quite a few sets made as they seem quite difficult to get hold of. I'm not interested in making any money off them, I just want to make them available to Seagull restorers around the world. And given the piss poor value of the Aussie Dollar at the moment, I expect they will be pretty cheap for anyone anywhere else in the world with a decent currency exchange.

So for the moment, I am a little stuck - I can't put the barrell/head back on until I get the new Head and Base Plates. Maybe I can used the old ones. What do you think? Here are a couple of photos of them after I have cleaned them up as well as I can.

Yeah - Chuck them out - I'll just have to wait to get my hands on some new ones. I guess, at a pinch, if I really have to - I can try to clean this up more and use them, but only if I cannot get my hands on some new ones - and only if getting them made myself if too expensive. I really don't want to use them, but if I can't get anything else - what choice have I got.

And I've just realised - the head gasket itself is missing. Above on this page I mentioned I wouldn't bore you with the details of getting the Head and the Barrel Separated. Well now I am going to. They were absolutely cemented together - rock solid - nothing I could do would even budge them, In the end I gave up (unusual for me - usually I keep going and break it!) and took it to an engine rebuild shop. As it turns out, they just did what I was going to do, bash the crap out of it with a hammer. When I got it back I could see the hammer marks all over it. But at last the head was off. But now I realise I never got the head gasket back, it must have been trashed in their delicate, almost surgical like precision procedure. To be fair though, I am guessing the last person who took the head off (perhaps the Seagull Factory) coated the gasket with some kind of RTV/Silicone sealant, and over the years it just cemented together.

No real issue though - the copper Head Gaskets are still available new from Saving Old Seagulls for under 10 pounds. ie: less than $20 Australian, but of course the postage from the UK is always pretty expensive.